Measure Sound Better

Vehicle & Vessel Airtightness Testing

The Importance of Air-Tightness Testing

Vehicle and vessel air-tightness testing assesses the effectiveness of seals during operation, ensuring there are no leaks under varying conditions. This process enhances both safety and performance.

Reduce noise intrusion

By testing air-tightness, users can repair relevant defects, reduce noise intrusion, and support the overall experience for end-customers.

Boost safety

Good air-tightness can prevent liquids from infiltrating vehicles and vessels, enhance overall strength and stability, and reduce the risk of accidents.

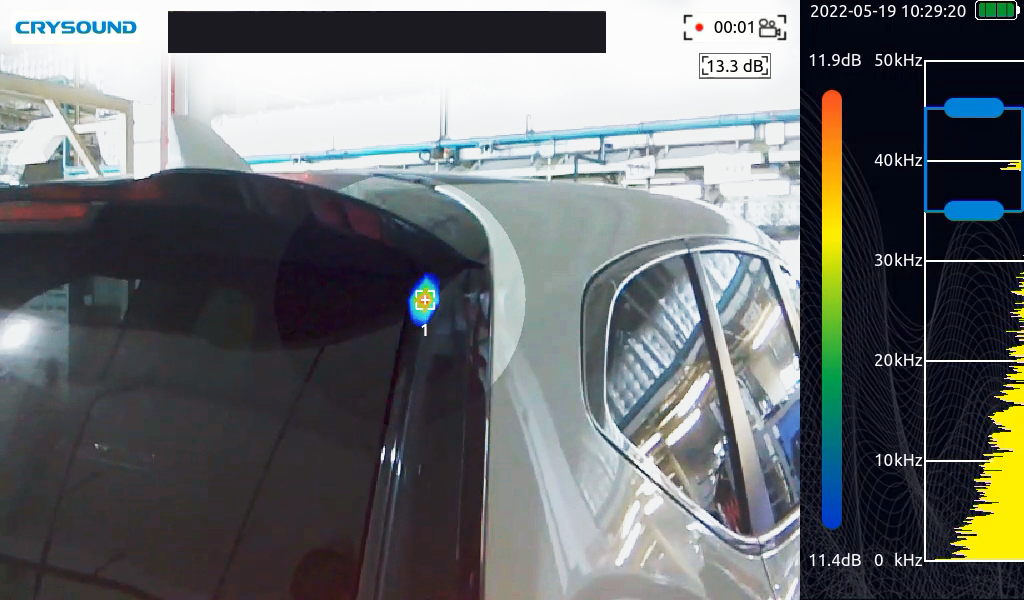

Non-Destructive Testing

No-contact scanning and testing of mating sealing surfaces enables non-destructive air-tightness testing of vehicles and vessels from a distance.

Does not impact the integrity of the object

Non-destructive testing does not cause any physical damage or alteration to the tested object and is suitable for high-value or critical safety components.

Save time and costs

Testing can be conducted without disassembly or interruption of the production process, reducing maintenance costs and downtime

High-Efficiency Detection

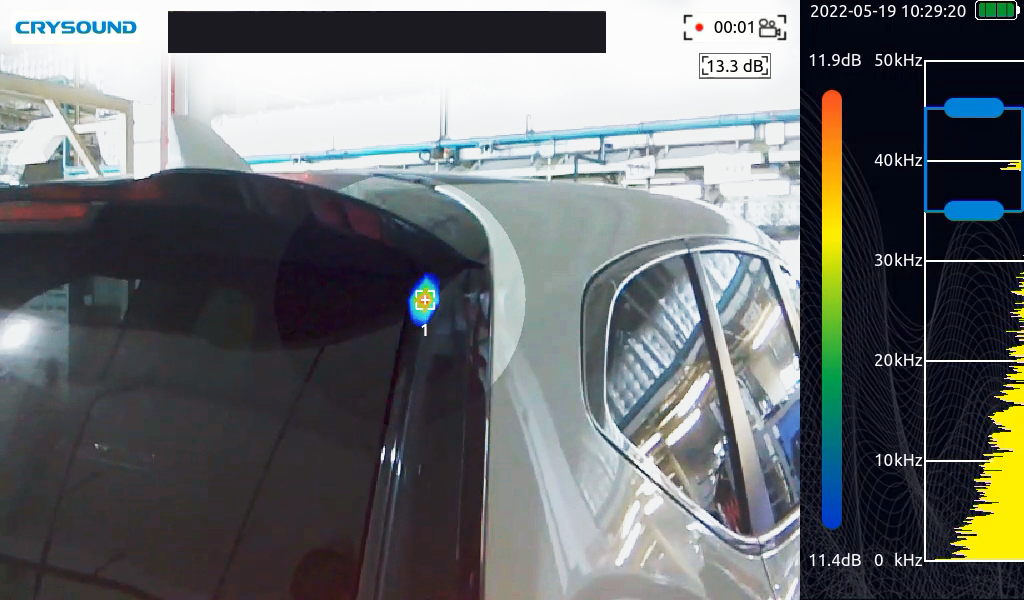

Acoustic imaging technology plays an important role in leak detection, improving testing efficiency and ensuring the safety and reliability of products.

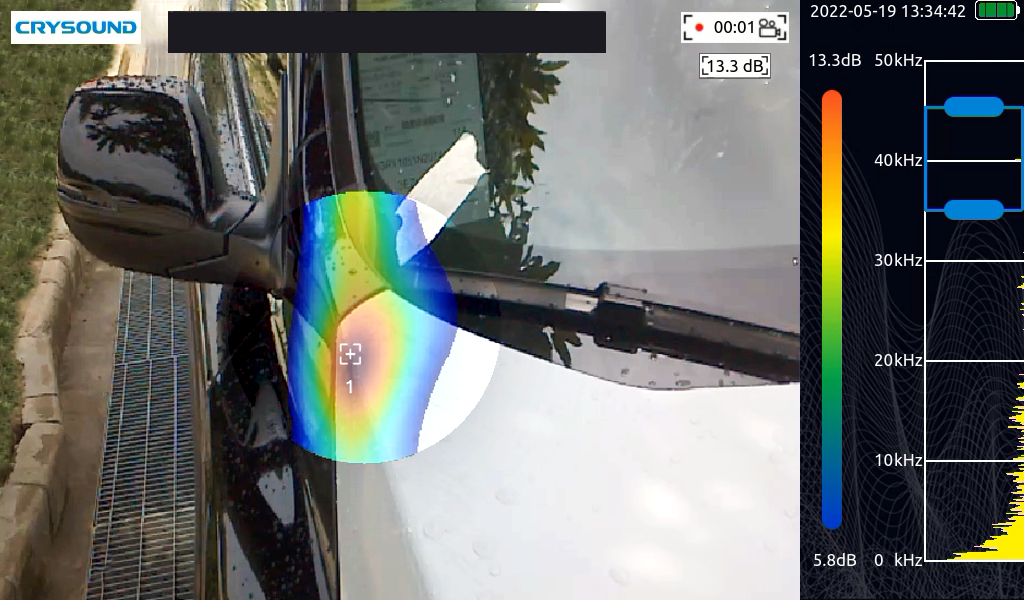

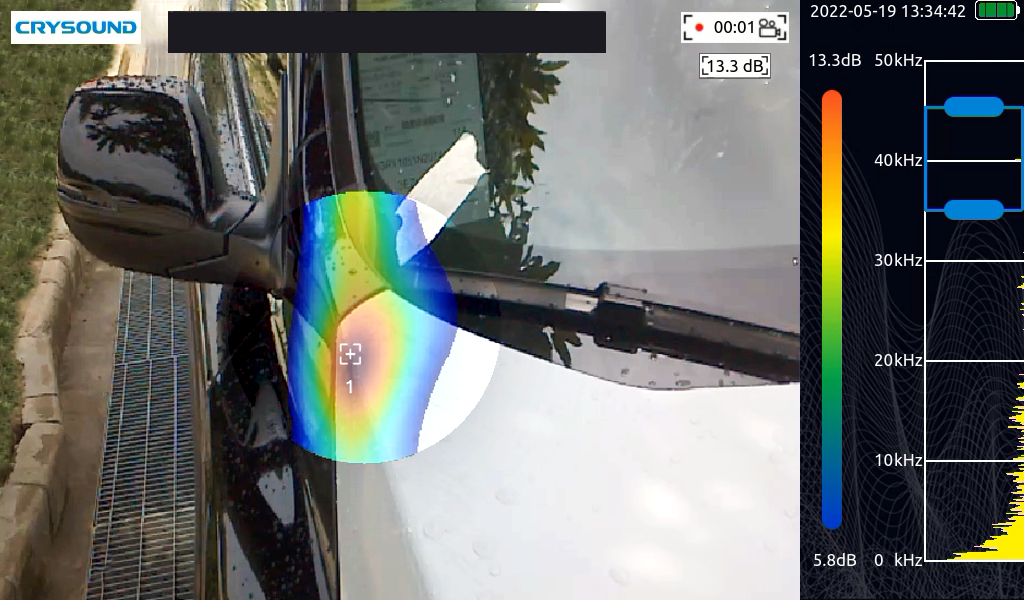

Real-time imaging

The device provides real-time images and data, allowing engineers to quickly analyze and make decisions.

Results visualization

The acoustic images are easy to understand and analyze, making the issues intuitive and facilitating communication.

System Devices

CRY2620 64-Mic Industrial Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

CRY8124 Advanced Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.