Measure Sound Better

Gas Leak Detection in a Negative Pressure Environment

Outdated Methods Lack Accuracy & Efficiency

The gas concentration alarm relies on gas entering the device, which can be problematic in a negative pressure environment. This makes it challenging to detect negative pressure leaks using the soap bubble method. Additionally, infrared detectors can be influenced by temperature variations. As a result, these methods may fail to identify negative pressure leaks and can lead to inefficiencies.

Low efficiency, missed leaks

A large number of vacuum devices results in low efficiency and a high likelihood of missed leaks during manual maintenance.

Traditional methods are ineffective

Under negative pressure, the "soapy water method" for detecting vacuum leaks can only be carried out during a facility shutdown.

Difficulty detecting leaks in hazardous areas

During inspections of pipeline flanges at high altitudes and extreme temperatures, personnel may encounter significant risks, including falls from heights, burns, and frostbite.

Use Case: Unlocatable Vacuum Leaks

As an example, a chemical company has struggled for an extended period to achieve the necessary vacuum level, impacting its production capacity. The factory's current detection methods are inadequate, requiring the system to be filled with nitrogen to increase pressure before using soapy water to identify leaks. This approach is both time-consuming and labor-intensive, leading to substantial financial losses.

Quickly locate vacuum leaks in minutes

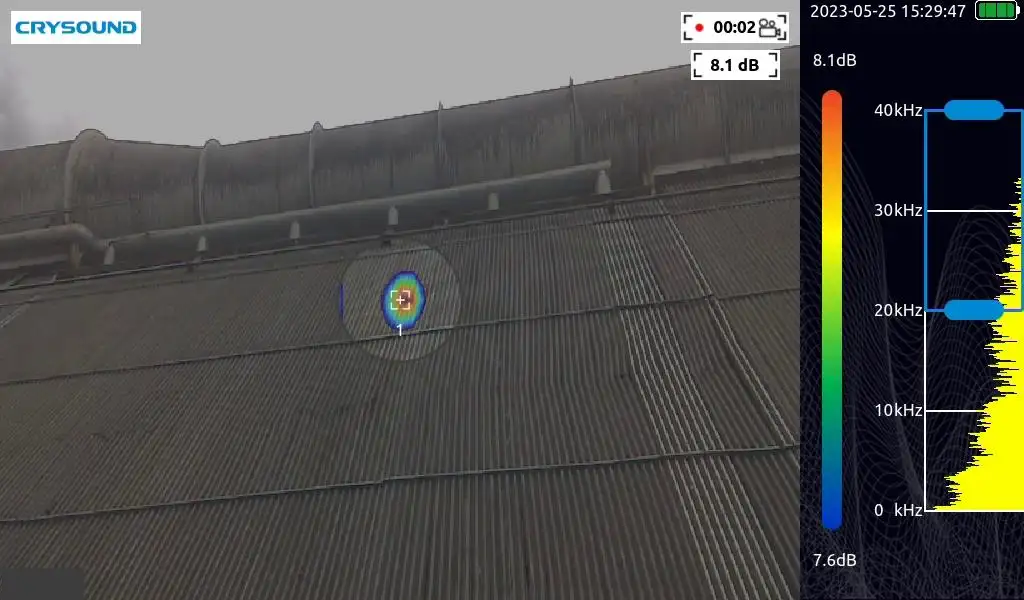

After the onsite technicians conducted an inspection using the acoustic camera, they were able to locate a critical vacuum leak position within minutes.

Reduced unnecessary downtime

Inspection teams efficiently covered large areas in a short time, minimizing both planned and unplanned downtime and reducing overall shutdowns.

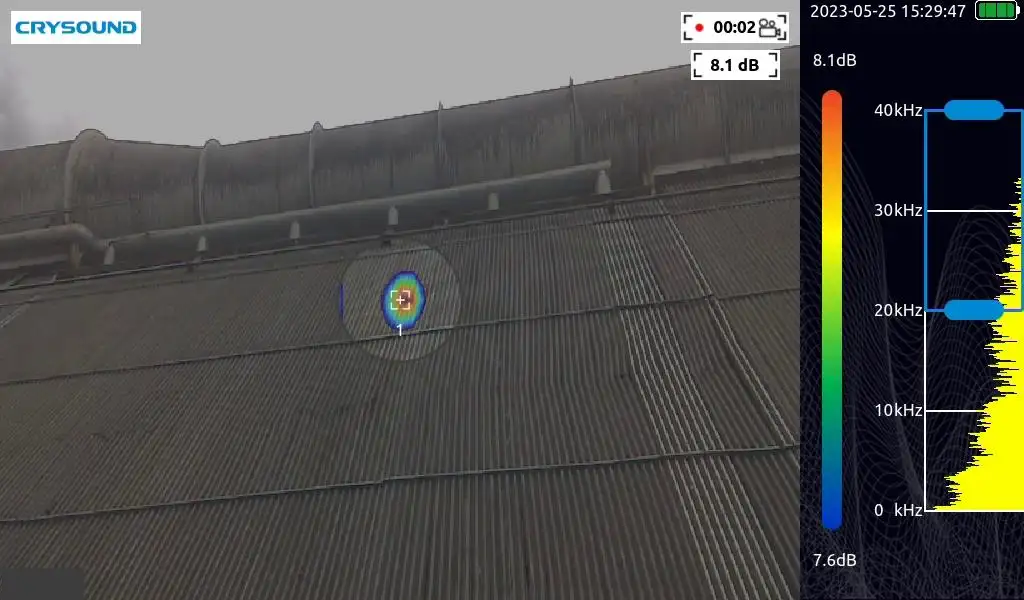

Use Case: Minimizing Safety Risks

As an example, a coal chemical company’s air-cooling pipeline carries high-temperature gas (70°C) under negative pressure. The thin pipe walls and aging equipment make it prone to leaks. While personnel using ultrasonic listening devices can identify a general area of the leak, they must approach closely to pinpoint the exact location, creating a immediate safety concern.

Quickly locate leaks

The acoustic imaging device features a 62° field of view, enabling it to scan and display multiple leaks simultaneously within its range, resulting in faster and more efficient detection.

No need for users to come in contact with high temperatures

Field personnel can accurately pinpoint the exact location of leaks using an acoustic camera, avoiding the need to endure high temperatures.

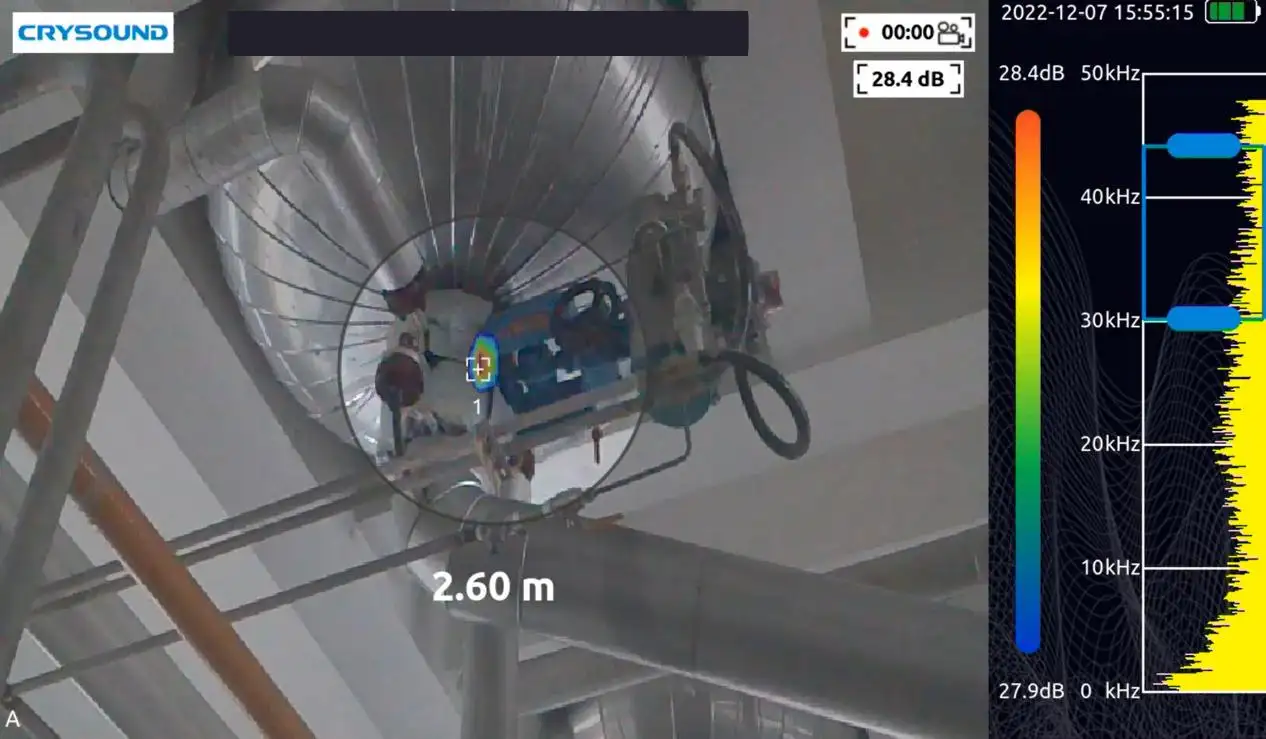

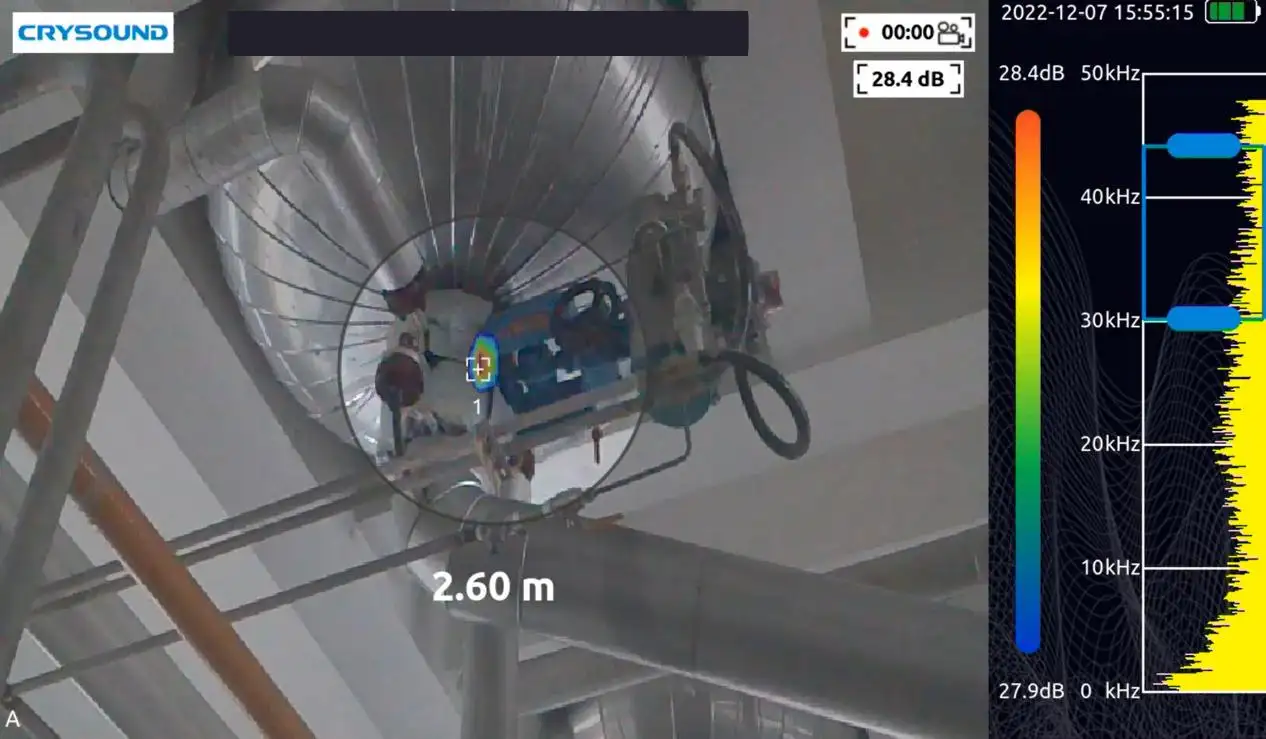

Use Case: Quickly Confirm Vacuum Leaks

As an example, a photovoltaic manufacturing company is experiencing a sudden drop in airflow within its negative pressure pipelines, which is failing to meet production requirements. Compounding the issue, there are no effective methods for detecting vacuum leaks. The exhaust ducts are both high and complex, and personnel currently assess potential leaks by physically touching the pipes, which exposes them to the risk of burns.

Improve efficiency and safety

Onsite personnel do not need to work at heights, they can use acoustic imaging devices to conduct remote leak detection from a safe distance.

No manual contact required

An acoustic imaging device is a non-contact, intelligent detection tool that eliminates the need for personnel to physically touch the equipment, enhancing safety in the process.

Remote + real-time imaging

Instantly identify leak points in the area, effectively avoiding energy waste and economic losses.

System Devices

CRY2620 64-Mic Industrial Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

CRY8124 Advanced Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.