Measure Sound Better

Gas Leak Detection for Energy Conservation & Emission Reduction

Supporting Carbon Neutrality

Energy conservation and emission reduction are crucial steps toward achieving carbon neutrality. To find effective solutions, a chemical company enlisted CRYSOUND for an on-site assessment. With energy costs for the factory's air compressors representing 30% of total expenses, the client wanted to understand how acoustic imaging technology can benefit their operations.

Old methods are outdated

Onsite pipelines and flanges may all be potential sources of leaks, and traditional leak detection methods are inefficient and inaccurate.

Missed leaks and poor decision-making

For our client, the existing leak detection methods depended on the subjective judgment of inspectors, which often resulted in missed leaks and inaccurate assessments.

Achieving Energy Conservation & Reduced Emissions

We sent two engineers to the client’s site for a week-long ultrasonic leak detection survey of the plant’s pipelines and equipment. They discovered over 100 leak points of varying severity and estimated the annual economic loss to be 800,000 yuan. These seemingly minor leaks have resulted in substantial financial losses for the plant.

Quickly locate leakage points

By using a cloud map, the leak points are displayed on the screen, allowing the client to locate and repair the leaks based on the images.

Assess economic losses

The equipment can assess the economic losses due to leaks, and the client can determine the necessity of repairs based on the results.

Detect Leaks & Equipment Faults

Acoustic imaging devices enable precise leak detection, identification of potential equipment faults, and improved operational efficiency for enterprises. Prompt repair of leaks reduces energy waste, significantly supporting the an organization's energy-saving and emission-reduction objectives.

Identify small, hidden, and inaccessible leaks

Acoustic imaging technology can detect low-level leaks from a distance of 0.5m ~ 120m, allowing for the identification of concealed leaks.

Save unnecessary resource losses

The device can perform range scanning and locate leaks, allowing users to quickly repair leak points and reduce energy waste.

Reduce greenhouse gas leaks

Carbon dioxide leaks generated during production can lead to violations of local regulations. An acoustic imaging device can quickly detect these leaks.

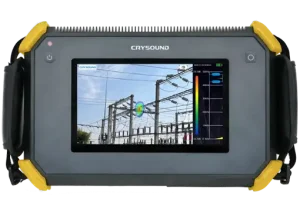

System Devices

CRY2620 64-Mic Industrial Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

CRY8124 Advanced Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.