Measure Sound Better

Gas Leak Detection in Explosion-Proof Scenarios

The Current State of Leak Detection

In the past, leak detection demanded substantial resources in terms of manpower, materials, and time, leading to high operational costs. For instance, using soapy water to identify leaks in a chemical plant could take several weeks. Furthermore, for safety reasons, leak detection was often limited to production shutdown periods, adding to the overall complexity and expense.

Improve detection efficiency by 10X

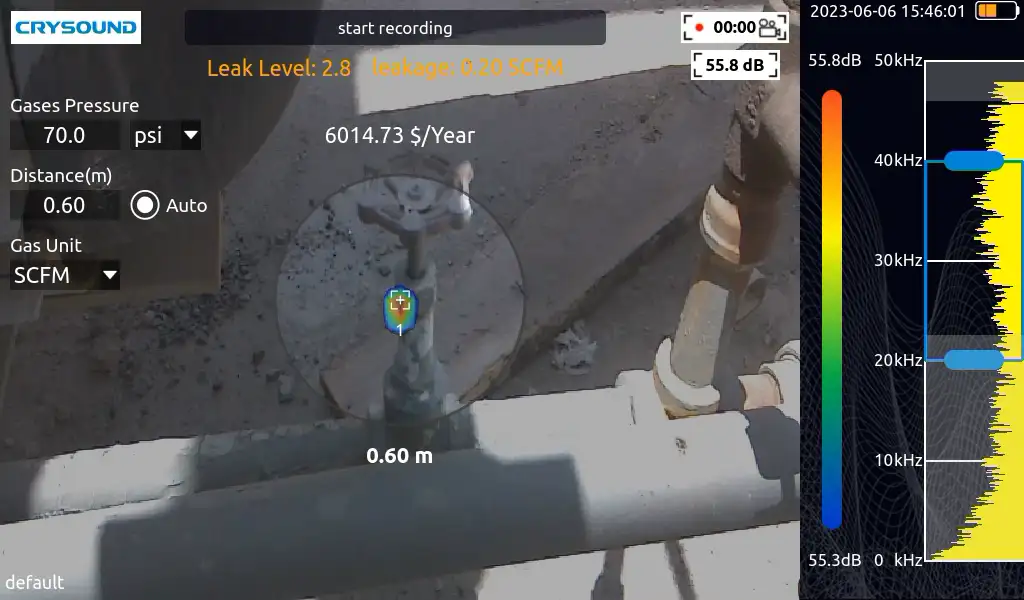

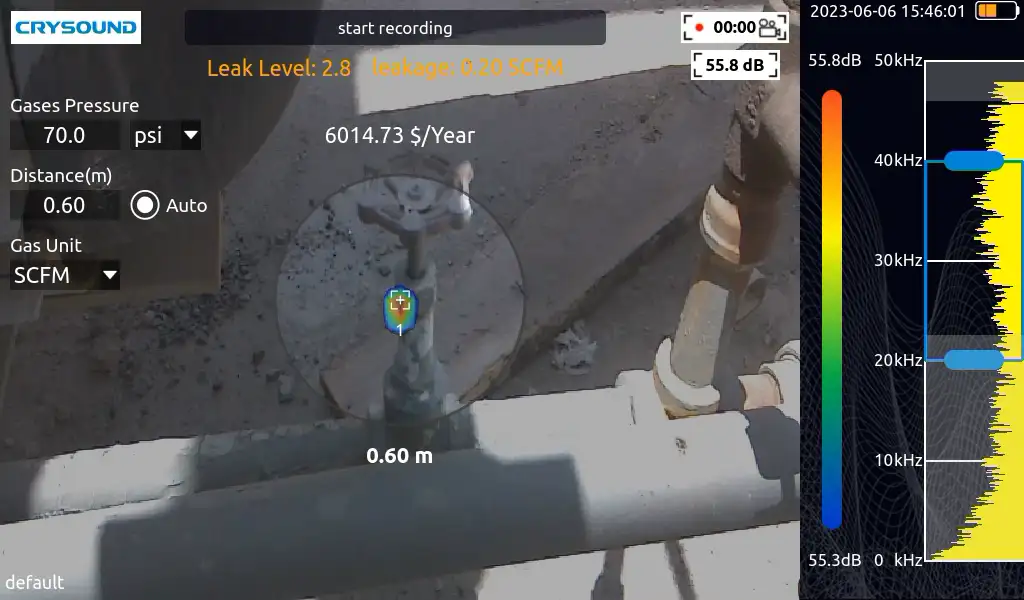

Real-time display of detection results improves detection efficiency and response capabilities.

A simple detection method

Aim the device at the area we need to evaluate and the detection results will be displayed.

Why Choose Acoustic Imaging Technology?

Unlike traditional leak detection methods like soapy water or gas concentration alarms, CRYSOUND utilizes advanced acoustic imaging technology to detect leaks. Our system identifies the distinct sound frequencies generated by gas leaks, enabling safe and efficient detection from a distance, regardless of the gas type.

Detects any type of gas

Regardless of the type of pressurized hazardous gas, users can detect any type of gas leak.

Long-distance detection

The device detects leaks from 0.3 ~ 120 m (1 ~ 393.7 ft), making climbing aids unnecessary.

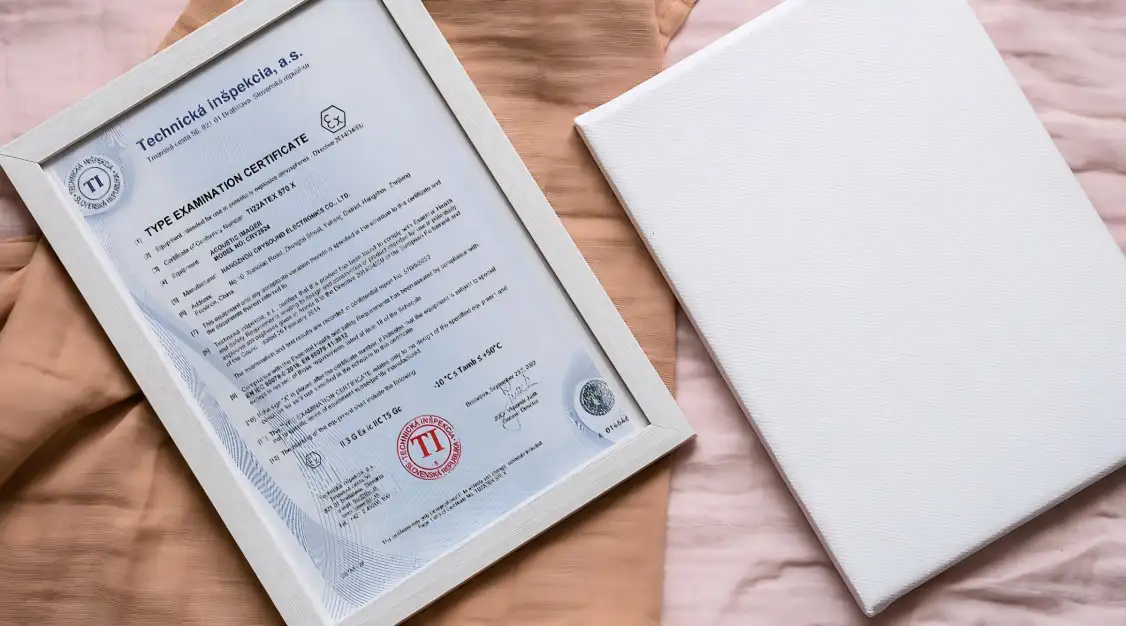

Suitable for Explosive Environments

The ATEX-certified CRYSOUND acoustic imaging camera has demonstrated exceptional effectiveness in detecting hazardous gases like hydrogen and acetylene, ensuring the safety and reliability of equipment in the field.

Explosion-proof requirements

The ATEX-certified device has been tested by a professional explosion-proof organization and obtained certification.

High accuracy

The device displays real-time detection results, quickly and accurately locating even the smallest gas leaks.

Save on Time & Cost

Chemical plants benefit greatly from acoustic imaging technology, which reduces the need for extensive materials, manpower, and time, ultimately driving down overall costs. This technology simplifies the detection of even small leaks of toxic or explosive gases, making it easier to align safety protocols with reliability objectives.

Better leak assessments

An acoustic imaging camera ensures all leak data is readily available, improving decision-making across various use cases.

Economic value analysis

Conduct the economic value analysis based on the assessed leakage volume, providing a more intuitive display of losses.

System Devices

CRY8125 Advanced Ex Acoustic Imaging Camera

CRY2623M Fixed Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.