Measure Sound Better

Acoustic Camera: The Complete Guide to Sound Source Localization

Table of content

An acoustic camera is one of the most powerful tools available to engineers who need to locate, visualize, and quantify noise sources in complex environments. Whether you are troubleshooting an unwanted rattle inside a vehicle cabin, tracking down air leaks in a compressed-air system, or verifying the acoustic performance of a home appliance on the production line, an acoustic camera can do in minutes what traditional measurement methods take hours—or fail to do at all.

This complete guide explains how acoustic cameras work, where they are used, what to look for when choosing one, and how they compare to conventional sound level meters. By the end, you will have a clear understanding of sound source localization technology and the confidence to select the right acoustic imaging camera for your application.

What Is an Acoustic Camera?

An acoustic camera is an instrument that combines a microphone array with a digital camera to produce a real-time visual map of sound—often called an acoustic image or sound map. The colored overlay shows exactly where noise is coming from, its relative intensity, and how it changes over time or frequency.

Unlike a single microphone, which can measure sound pressure at one point but cannot tell you where the sound originates, an acoustic camera performs noise source identification across a wide field of view simultaneously.

Core Components

| Component | Role |

|---|---|

| Microphone array | Captures sound at multiple spatial positions |

| Digital camera | Provides the optical reference image |

| Data acquisition hardware | Digitizes and synchronizes all microphone channels |

| Beamforming software | Computes the sound map from array data |

How Does an Acoustic Camera Work? The Beamforming Principle

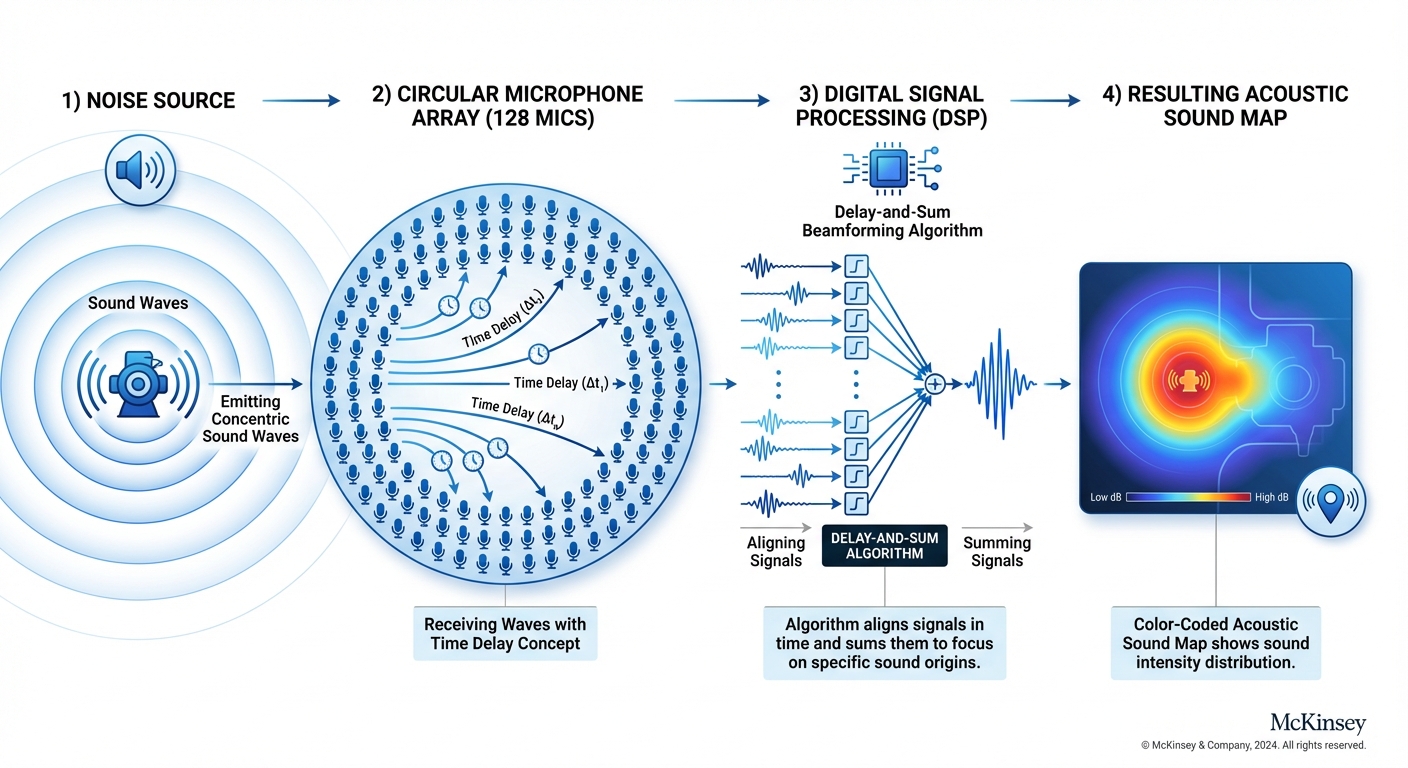

The physics behind an acoustic camera relies on a technique called beamforming. Here is a simplified explanation:

- Sound waves arrive at the microphone array. Because microphones are at different positions, the same wavefront reaches each microphone at a slightly different time.

- Time delays are calculated. For every candidate point in the measurement space, the software calculates the expected arrival-time differences across all microphones.

- Signals are shifted and summed. The software shifts each microphone signal by the predicted delay and sums them. If the candidate point is the true source, the signals add constructively, producing a strong peak. If not, they partially cancel.

- A sound map is generated. By scanning thousands of candidate points, the algorithm builds a 2D (or 3D) color map of acoustic intensity overlaid on the camera image.

This process is called delay-and-sum beamforming and is the foundation of most acoustic cameras. More advanced algorithms—such as CLEAN-SC, functional beamforming, and deconvolution approaches—further sharpen the image and improve dynamic range.

Frequency Range and Array Design

The usable frequency range of an acoustic camera depends on the array geometry:

- Low-frequency limit is governed by the overall array diameter. A larger array resolves lower frequencies.

- High-frequency limit is governed by the spacing between adjacent microphones. Closer spacing avoids spatial aliasing at higher frequencies.

Typical acoustic cameras cover 200 Hz to 12 kHz or wider, with some specialized arrays reaching above 20 kHz for applications like leak detection.

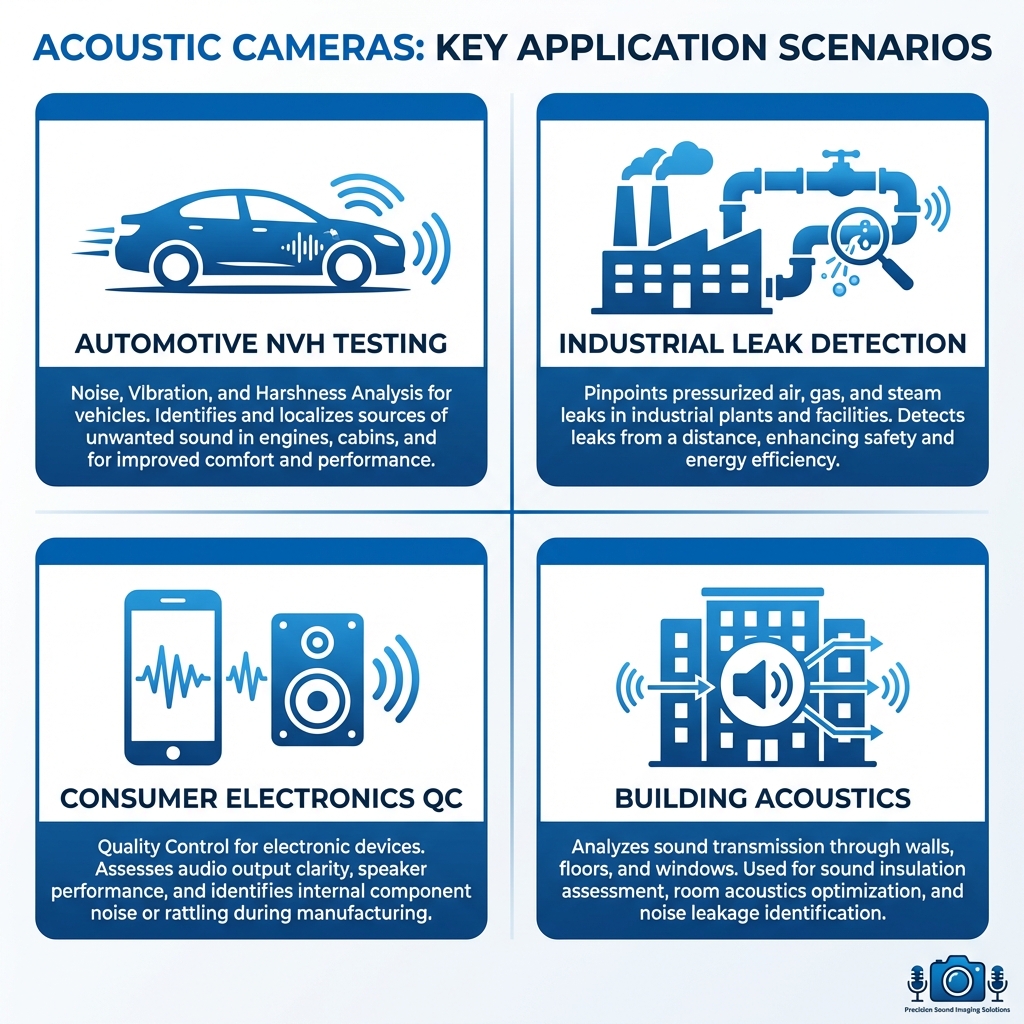

Applications of Acoustic Cameras

Automotive NVH (Noise, Vibration, and Harshness)

Acoustic cameras are indispensable in automotive development. Engineers use them to:

- Identify wind noise sources around door seals, mirrors, and A-pillars in wind-tunnel tests.

- Locate interior noise paths—dashboard rattles, HVAC duct noise, powertrain radiation—during road tests.

- Validate pass-by noise levels under ISO 362 by mapping exterior noise sources in real time.

Home Appliance Noise Reduction

Consumer expectations for quiet appliances are rising. Manufacturers of washing machines, refrigerators, dishwashers, and air conditioners use acoustic cameras to:

- Compare noise signatures before and after design changes.

- Detect abnormal noise patterns in end-of-line (EOL) quality checks.

- Pinpoint noise from specific subcomponents (compressors, fans, pumps) within a fully assembled product.

Industrial Equipment and Predictive Maintenance

In factories, acoustic cameras quickly identify:

- Compressed-air leaks, which account for 20–30% of energy waste in many plants.

- Bearing defects in motors, turbines, and conveyors—often before they become audible to the human ear.

- Electrical discharge (partial discharge) in high-voltage switchgear and transformers.

Building Acoustics and Environmental Noise

Acoustic cameras help building consultants identify sound transmission paths through walls, windows, and HVAC penetrations, verify the effectiveness of sound barriers, and map noise from construction sites.

Power Generation and Renewable Energy

Wind turbine manufacturers and operators use acoustic cameras to measure blade noise, detect trailing-edge damage, and comply with environmental noise limits.

How to Choose an Acoustic Camera

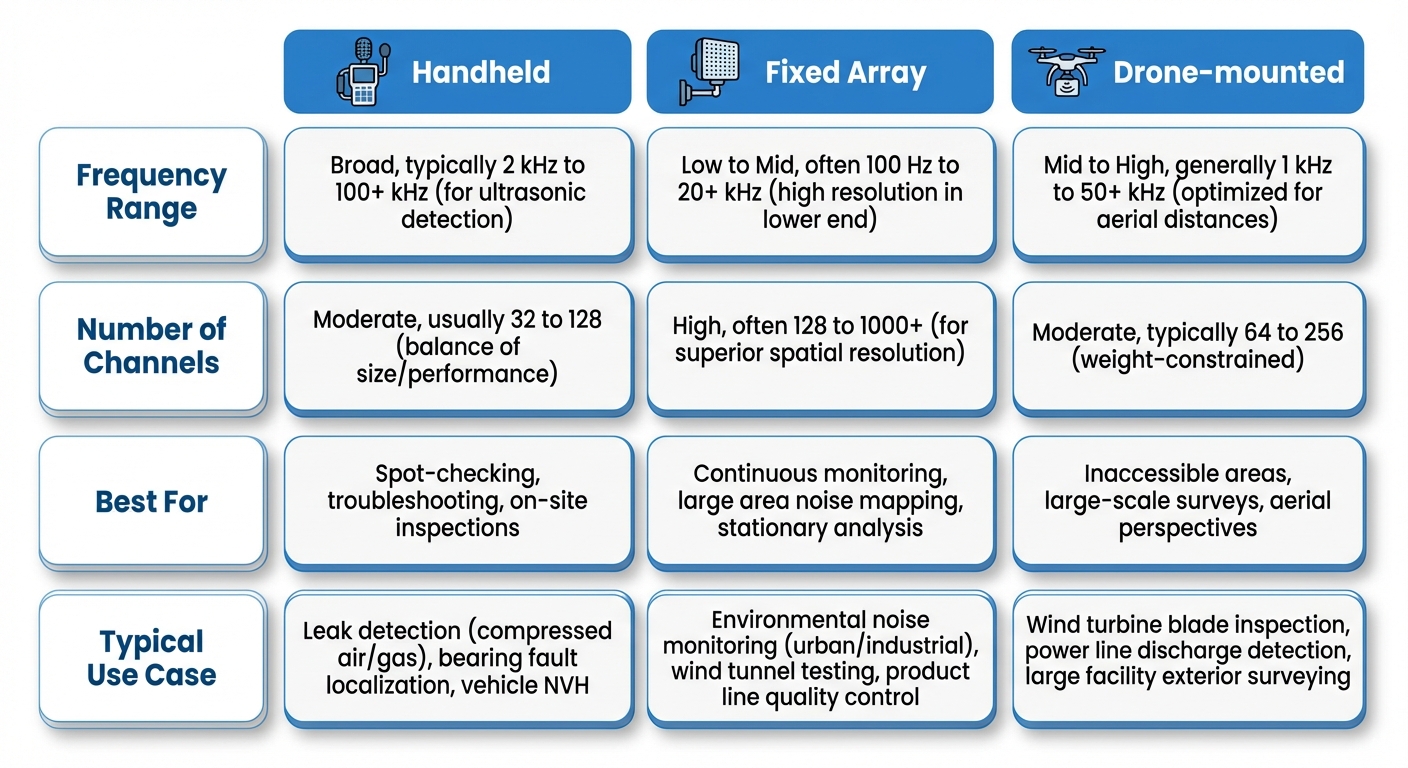

1. Array Configuration and Size

- Planar arrays (flat) are the most common—lightweight, portable, and suitable for front-facing measurements.

- Spherical or 3D arrays capture sound from all directions for interior cabin or room acoustic studies.

- Number of microphones: More microphones improve spatial resolution and dynamic range. Entry-level: 30–64; high-performance: 100–200+.

2. Frequency Range

| Application | Typical Frequency Range |

|---|---|

| Automotive NVH (interior) | 200 Hz – 8 kHz |

| Appliance noise | 300 Hz – 12 kHz |

| Air leak detection | 2 kHz – 20 kHz+ |

| Building acoustics | 100 Hz – 5 kHz |

3. Software Capabilities

Real-time beamforming, advanced algorithms (CLEAN-SC, deconvolution), time-domain and frequency-domain analysis, video recording with synchronized audio, and flexible export formats.

4. Portability and Ease of Use

For field measurements, a lightweight, battery-powered, single-person-operable system is essential.

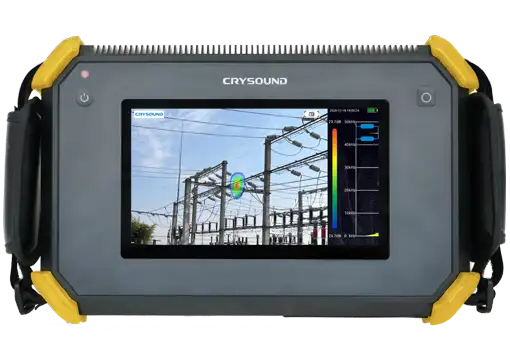

A Closer Look: CRYSOUND Acoustic Imaging Systems

- The CRY8124 is a large-format planar array with 200 MEMS microphones, optimized for high-resolution measurements in automotive NVH and industrial applications.

- The CRY2623 is a compact, handheld acoustic camera with 128 microphones designed for rapid field inspections—air leak detection, electrical inspection, and predictive maintenance.

Both systems include real-time beamforming software with CLEAN-SC deconvolution, video overlay, and spectral analysis.

Acoustic Camera vs. Sound Level Meter: When to Use Which

| Criterion | Sound Level Meter | Acoustic Camera |

|---|---|---|

| What it measures | Sound pressure level at one point | Sound source location and relative level across a surface |

| Source identification | No | Yes—visual map shows source locations |

| Regulatory compliance | Yes—traceable dB(A)/dB(C) values per IEC 61672 | Limited |

| Cost | $500–$5,000 | $15,000–$150,000+ |

| Best for | SPL measurement, noise monitoring, compliance | Root-cause analysis, noise reduction, leak detection |

In practice, the two tools are complementary. A sound level meter confirms how loud a problem is; an acoustic camera shows where it is.

Conclusion

Acoustic cameras have transformed the way engineers approach noise problems. By making sound visible, they accelerate root-cause analysis, reduce development cycles, and enable quality controls that were previously impractical.

Ready to see your noise sources? Contact CRYSOUND for a personalized consultation or request a live demo with your application.

Related Products

IA3104 Contact Ultrasound Sensor

CRY3408-S01 Pressure-field Prepolarized High-level Microphone Set, 1/4", 0.14mV/Pa

CRY3408 Pressure-field Microphone, 1/4",Prepolarized high-level,0.14 mV/Pa

CRY578 Bluetooth LE Audio Interface

CRY8500 Series SonoCam Pi Acoustic Camera

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.