Measure Sound Better

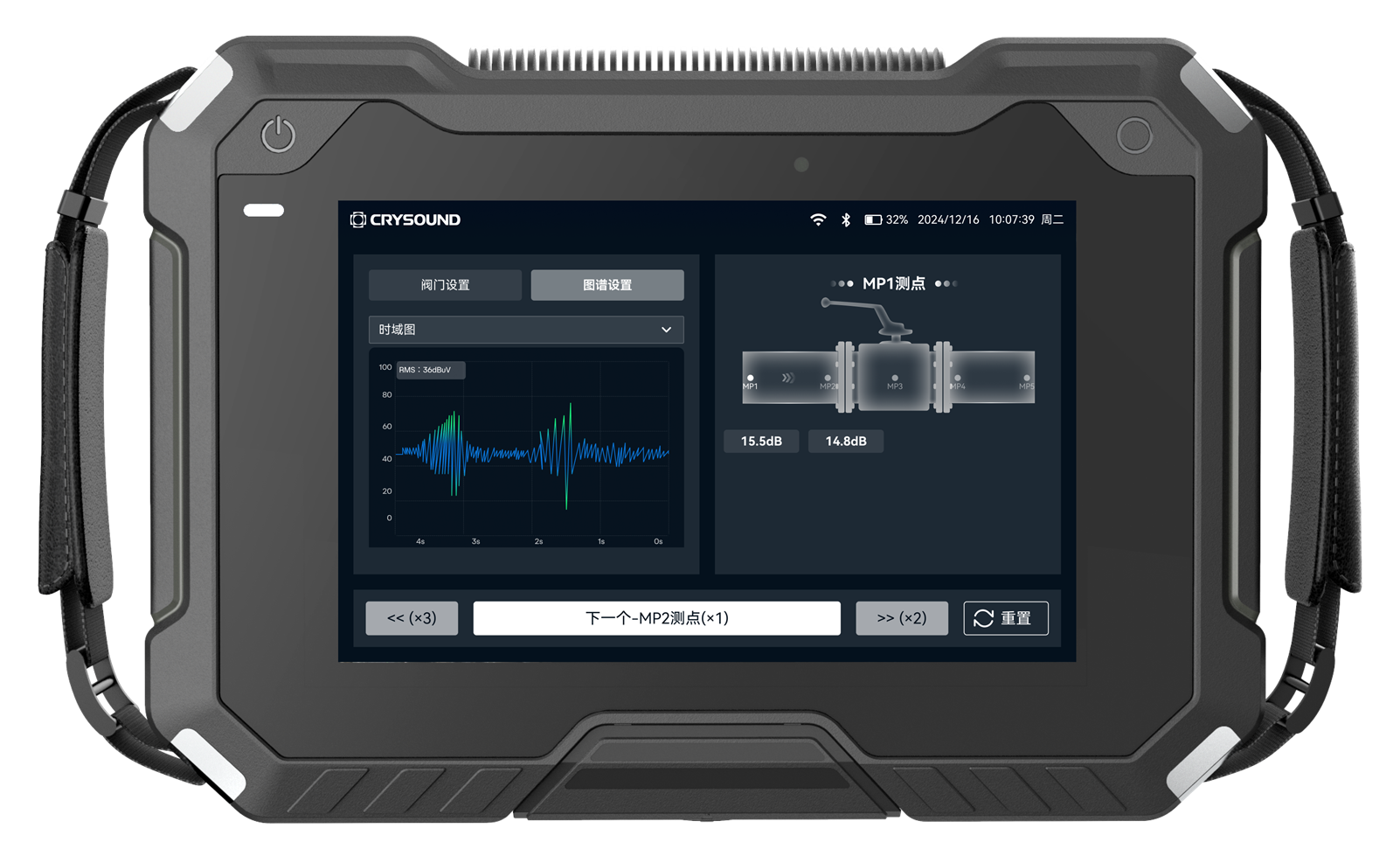

IA3104 Contact Ultrasound Sensor

The Contact Ultrasound Sensor is designed for detecting leakage in pressurized gas and liquid valves. Using contact ultrasonic sensing, ultrasound energy travels through the metal surface, and accurately captures high-frequency ultrasonic signals generated by internal valve leakage. Combined with intelligent analytics and a guided workflow, it automates the full process—from data acquisition and feature extraction to leak diagnosis—improving inspection efficiency and consistency in industrial environments. It is ideal for preventive maintenance and fault diagnostics of critical assets such as oil pipeline valves and natural gas network valves, supporting predictive maintenance decisions.

Technical Specifications

Main Features

Product Highlights

Simplified Valve Leak Inspection

Replace experience-based “listen, observe, and record” with a standardized inspection workflow. The software guides ultrasonic data collection at measurement points, automatically analyzes results, and presents clear conclusions—no manual logging or post-processing required. Inspections become faster, more accurate, and more repeatable.

Non-Intrusive Testing

No valve disassembly is required. Simply attach the sensor to the valve body or adjacent pipe surface to perform testing. Suitable for ball valves, plug valves, check valves, butterfly valves, and other common valve types—supporting leak screening and condition verification without interrupting production.

Automatic Leak Diagnosis

The system evaluates key signal features such as sound level (dB), spectrum characteristics, and energy indicators. The Valve Leak intelligent algorithm, powered by a field-validated model and historical case data, automatically classifies valve condition as “Normal / Suspected Leak / Leak Detected” and supports cross-condition comparison and verification—Reducing the need for complex manual signal interpretation.

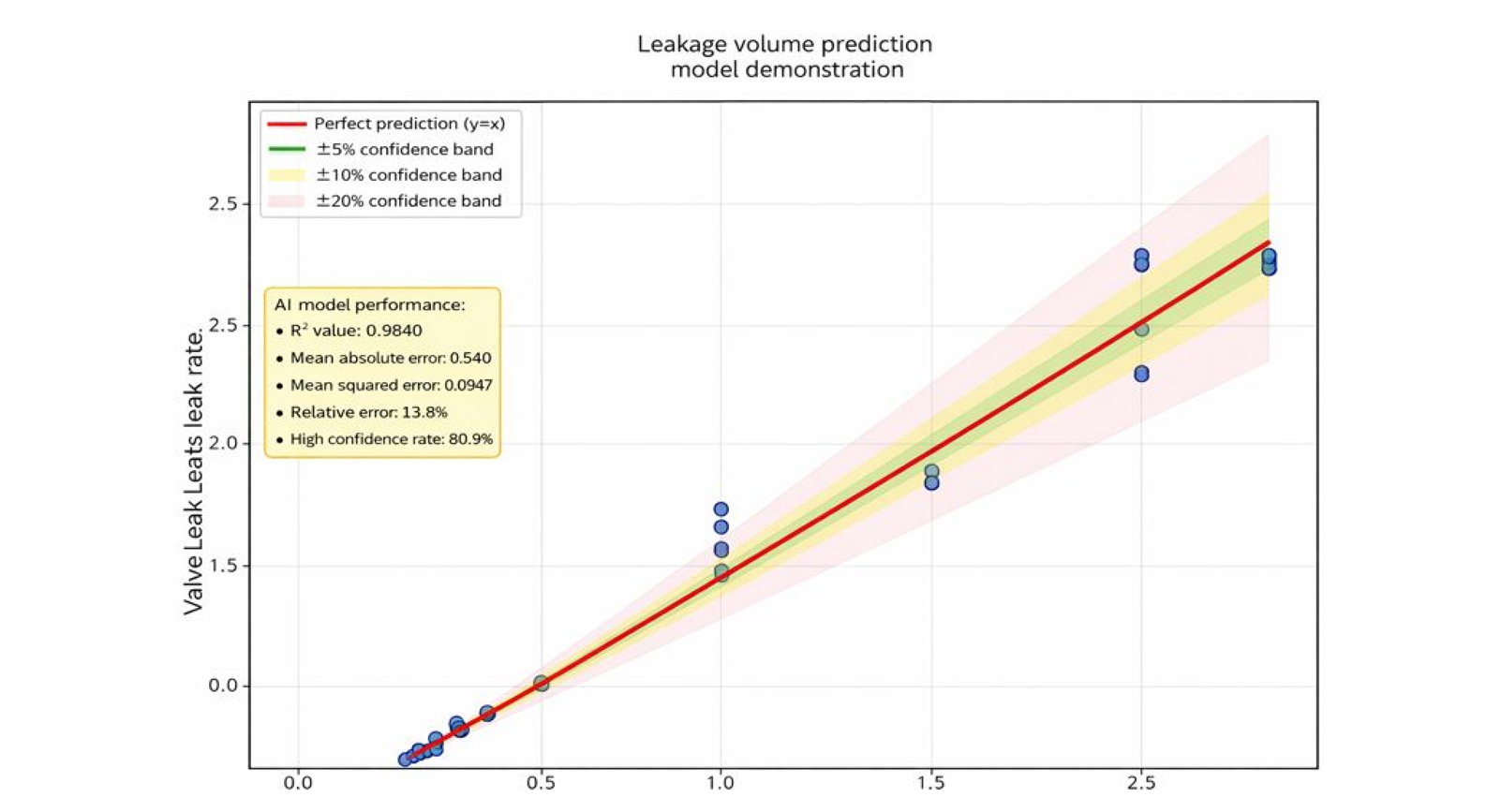

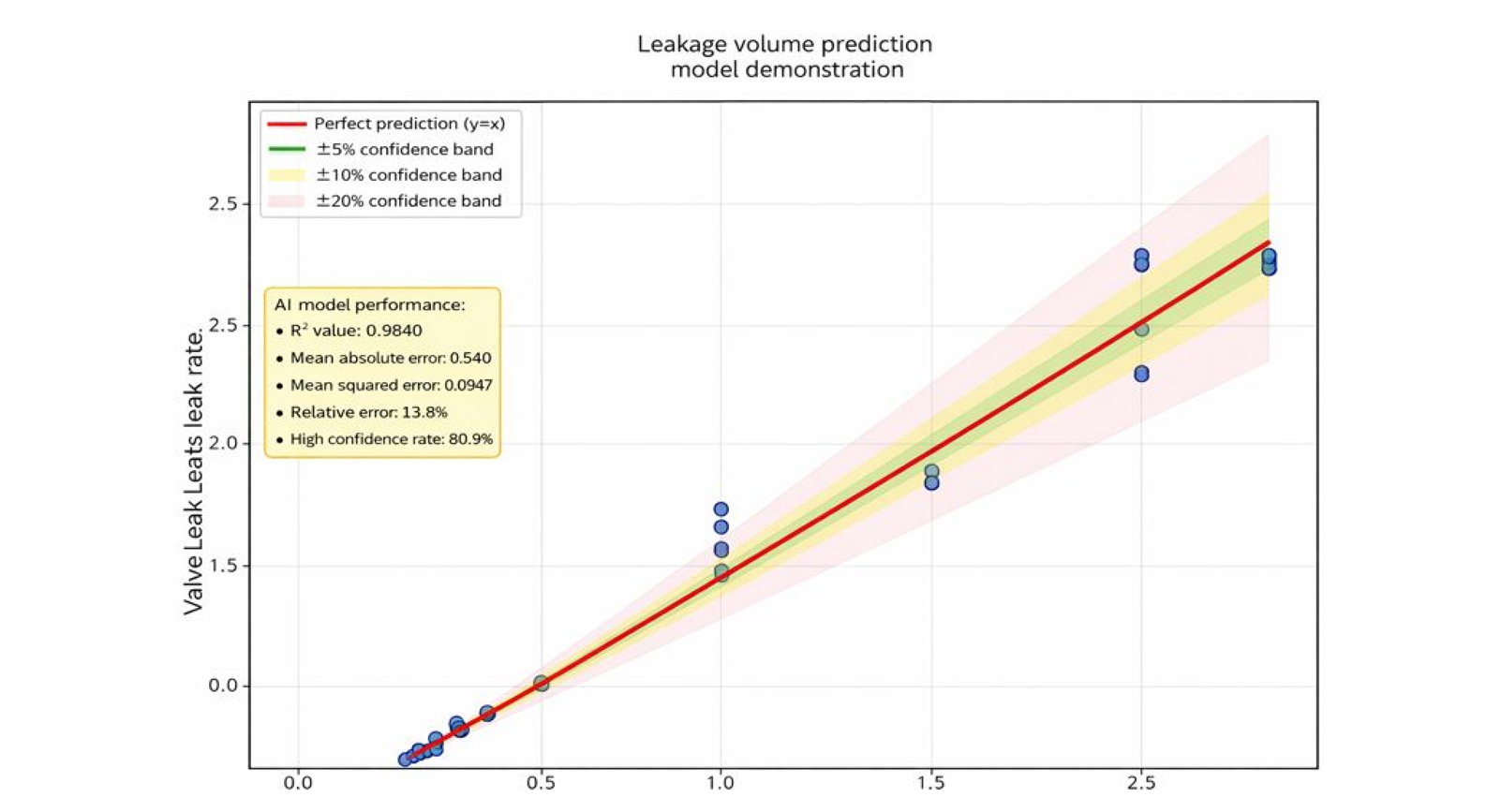

Leak Rate Estimation

Beyond a simple leak/no-leak result the solution quantifies leak severity by estimating leakage level or leakage rate based on ultrasonic features. This provides actionable guidance for maintenance decisions such as “monitor,” “schedule repair,” or “prioritize replacement,” helping close the loop from detection to corrective action.