Measure Sound Better

Airtightness Testing of Composite Materials

Accelerate Airtightness Testing of Composites

Composite materials are widely utilized in the wind energy sector. Gas permeability testing of these materials is primarily conducted to assess their ability to prevent the penetration of gases or liquids, ensuring optimal product performance in various environmental conditions.

Existing technology is inefficient

The existing methods for detecting the gas tightness of composite materials require the establishment of complicated testing environments, and the testing efficiency is extremely low.

Inspections are unreliable

The existing gas tightness detection technologies mainly rely on the subjective judgment of inspectors, which can easily lead to errors, increasing the difficulty of testing.

How Acoustic Imaging Detects Vacuum Leaks

Vacuum leaks produce ultrasonic waves, which are captured by the microphone array of the CRYSOUND acoustic imaging device. By processing these signals in real time, the device can quickly and accurately pinpoint the exact location of leaks. This technology allows anyone to perform comprehensive, reliable, and actionable leak detection with ease.

Background noise filtering

CRYSOUND acoustic imaging devices actively filter background noise while detecting leaks, even in noisy environments.

Easy-to-use for anyone

The devices are easy-to-use so anyone can find leaks reliably. Videos and pictures from the camera are easy to interpret.

Non-Destructive Testing

No-contact scanning and testing of mating sealing surfaces from a distance enable non-destructive air-tightness testing of vehicles and vessels.

Creates no damage

CRYSOUND devices do not cause any physical damage to the object being tested, making it suitable for negative pressure detection of blades.

Save time and costs

The detection process is simple and significantly reduces detection time and decreases errors.

High-Efficiency Detection

Acoustic imaging is a novel technology that provides a real-time visualization of leaks from a distance. With an acoustic imaging camera, anyone can pinpoint vacuum leaks 10x faster than traditional methods.

Real-time imaging

CRYSOUND devices provide real-time images and data, allowing engineers to quickly analyze and make decisions.

Results visualization

The acoustic images are easy to understand and analyze, identifying leaks in seconds.

System Devices

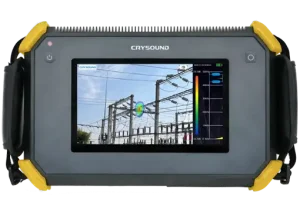

CRY2620 64-Mic Industrial Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

CRY8124 Advanced Acoustic Imaging Camera

Explore More Cases

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.