Measure Sound Better

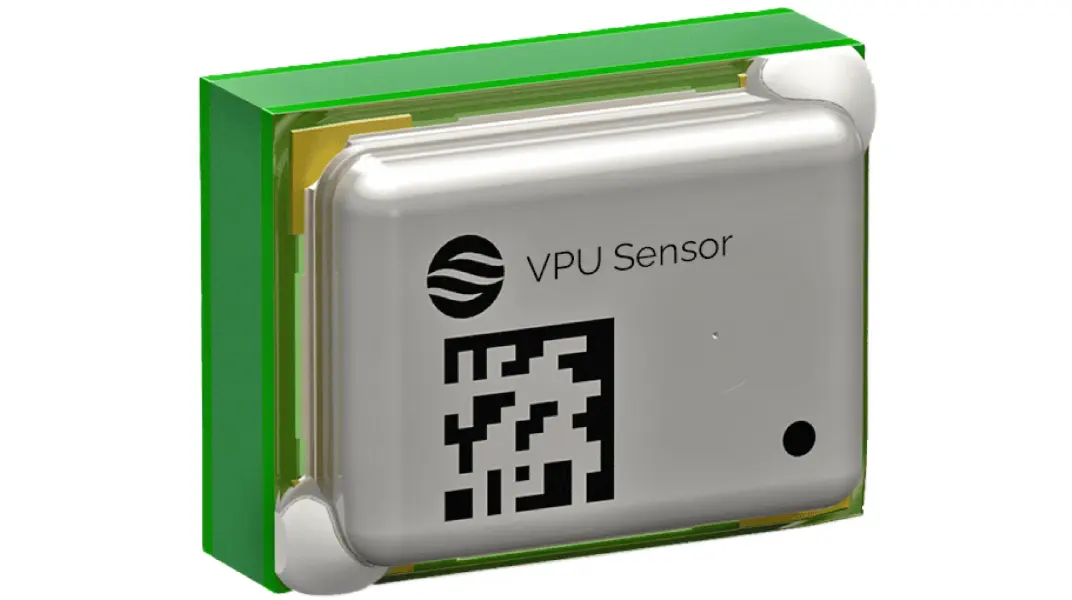

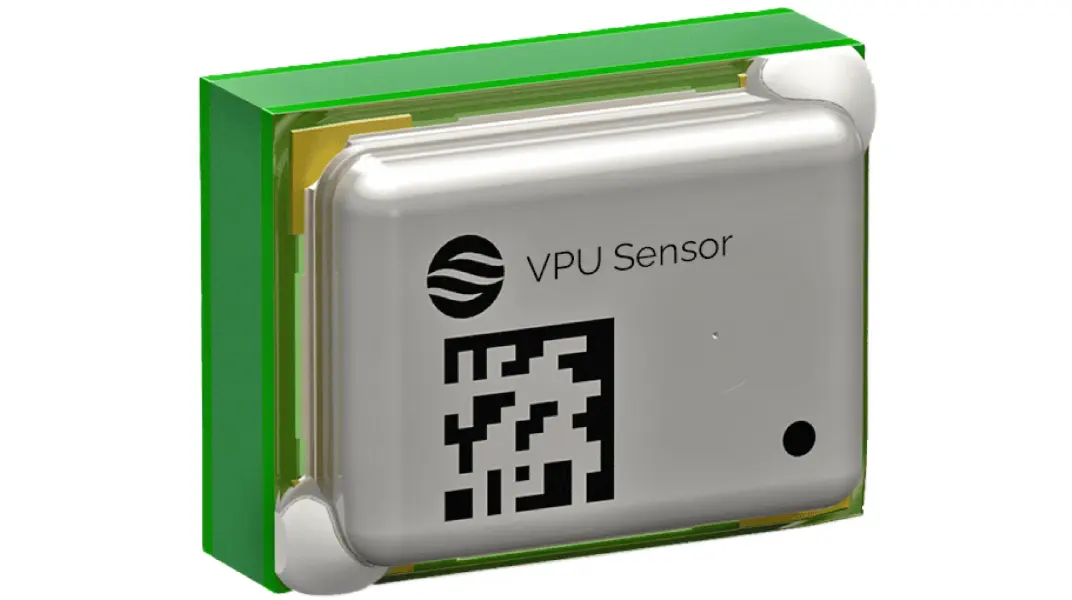

Smart Wearable VPU Test System

Overview

CRYSOUND provides a professional VPU test solution for bone-conduction voice applications in smart wearable devices, including TWS earbuds, OWS headsets, and AR glasses. This solution is designed to address the testing requirements of bone-conduction pickup under actual structural vibration conditions, providing stable, reliable, and production-ready measurement methods.

Based on advanced electroacoustic test technology, the solution integrates precision vibration excitation, high-sensitivity acceleration sensors, and intelligent signal analysis algorithms. It effectively suppresses airborne sound interference and accurately reflects the operating characteristics of the VPU under bone-conduction conditions.

Through precise measurement of key parameters such as frequency response, sensitivity, and distortion, the system helps customers maintain consistent and stable voice performance during both R&D validation and mass production testing, ensuring quality consistency for next-generation smart wearable products.

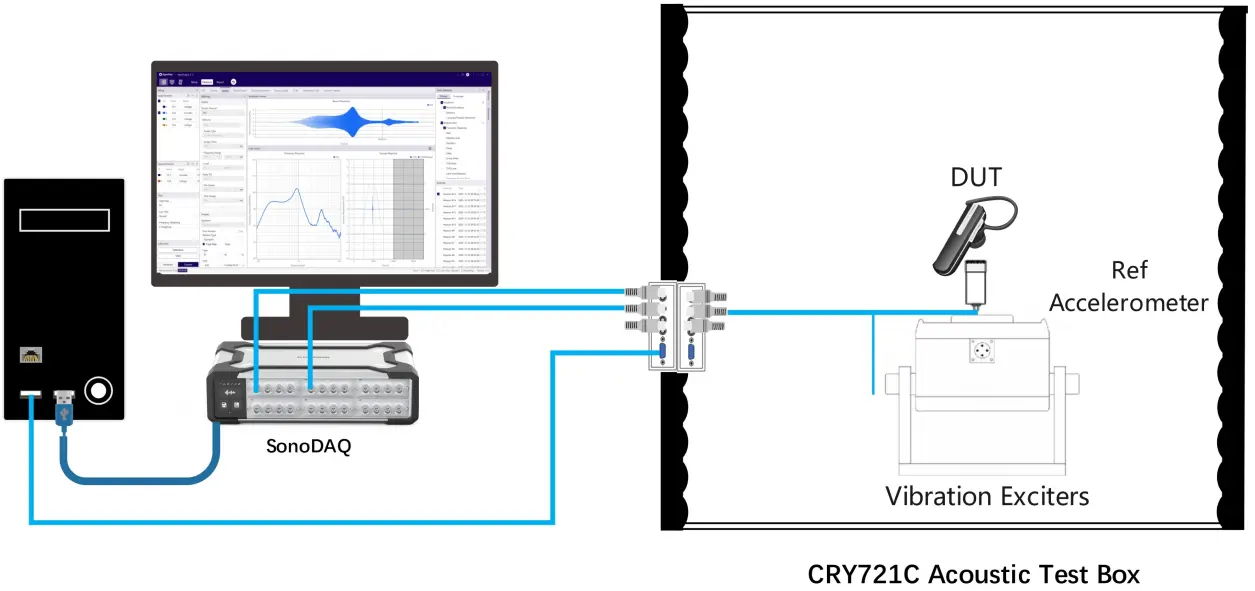

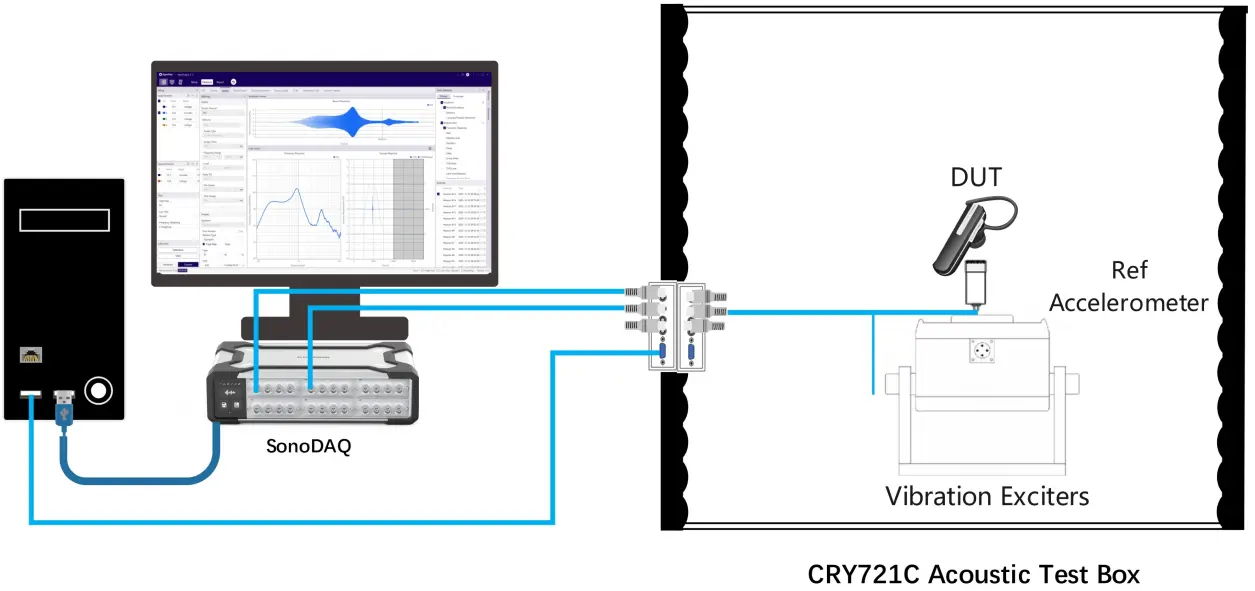

System Block Diagram

- > The host PC controls the Bluetooth dongle to connect to the device under test (DUT) and initiate production testing

- > The vibration table outputs swept-frequency signals, and the VPU records audio data, which is transmitted back via the Bluetooth dongle

- > The Bluetooth dongle controls the DUT to play swept signals, while the acceleration sensor collects vibration response data

- > The host software analyzes the data and outputs test results

Features

- High-Precision Bone-Conduction VPU Measurement

By combining vibration excitation simulation, high-sensitivity acceleration sensors, and intelligent signal analysis algorithms, the system establishes a complete bone-conduction test chain. This effectively isolates airborne sound interference and accurately reproduces the VPU’s operating state under structural vibration conditions.

The system enables stable and accurate measurement of key VPU parameters, including frequency response, sensitivity, and total harmonic distortion (THD). The high repeatability of test results provides reliable support for product development, performance comparison, and production qualification.

- Stable Acoustic Test Performance Suitable for Mass Production

When used together with shielded acoustic enclosures and standardized test fixtures, the solution effectively reduces the impact of environmental variations on test results. This ensures consistency and comparability across different test stations and production batches.

With a highly automated overall test process, the solution meets the stable testing requirements of TWS earbuds, OWS headsets, and AR glasses in large-scale mass production.

System Devices

CRY8124 Advanced Acoustic Imaging Camera

CRY2623 128-Mic Industrial Acoustic Imaging Camera

CRY2624 128-Mic Industrial Acoustic Imaging Camera (ATEX)

CRY2623M Fixed Acoustic Imaging Camera

CRY2626G Drone-Mounted Acoustic Imaging Camera

CRY2833 Sound Level Meter

Get in touch

If you are interested or have questions about our products, book a demo and we will be glad to show how it works, which solutions it can take part of and discuss how it might fit your needs and organization.